Articles

How To Store Completed Puzzles

Modified: March 2, 2024

Learn how to store completed puzzles with our informative articles. Discover practical tips and creative storage solutions to keep your puzzles intact and organized.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

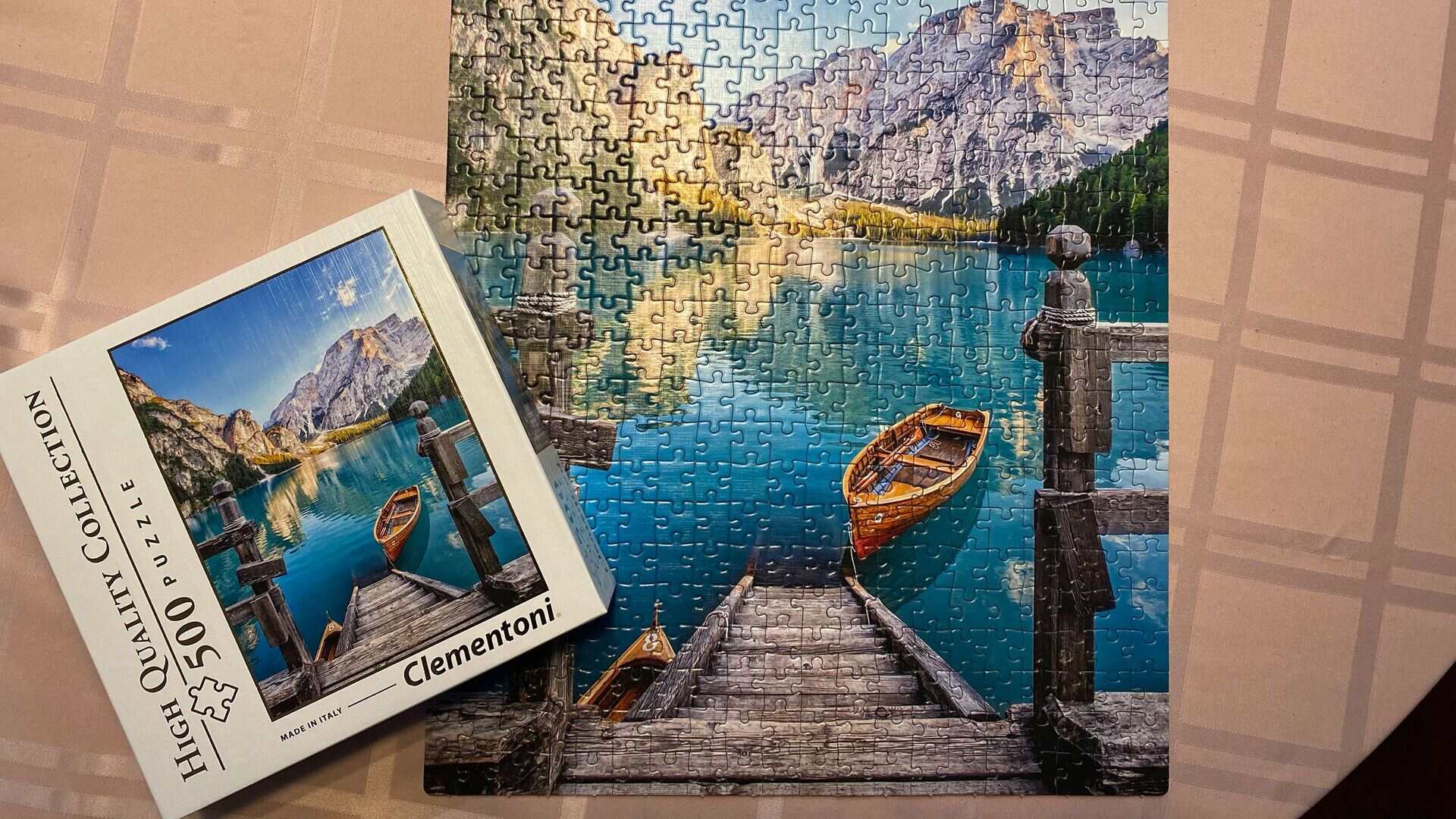

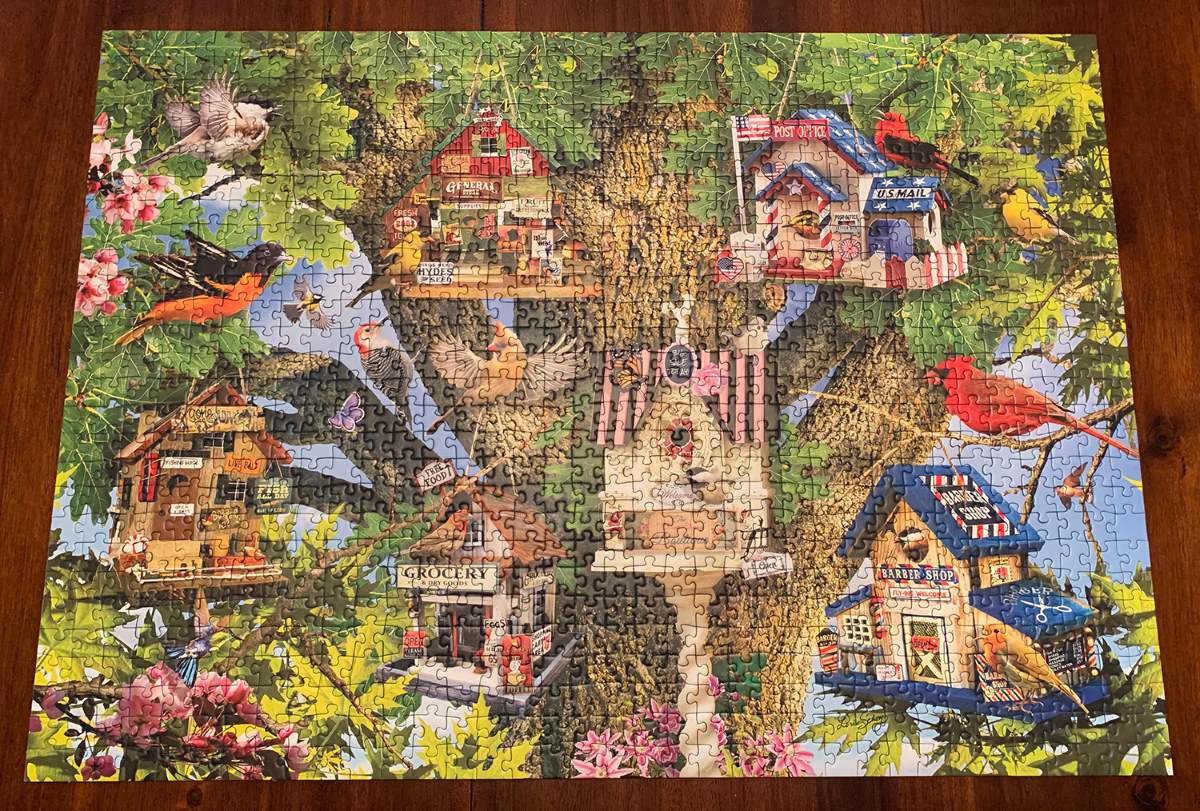

Completing a jigsaw puzzle can be incredibly satisfying. It’s a testament to patience, focus, and problem-solving skills. But what do you do once your masterpiece is finished? How do you store your completed puzzles to protect them and keep them intact?

In this article, we will explore various methods and techniques for storing completed puzzles. Whether you’re a casual puzzler or a dedicated enthusiast, these storage solutions will help you preserve your completed puzzles and keep them safe for years to come.

When it comes to storing puzzles, there are several options available. Each method has its pros and cons, so it’s essential to consider your preferences, available space, and the size of your completed puzzles.

From traditional puzzle storage methods to more innovative solutions, let’s take a closer look at the different approaches and find the one that suits your needs.

Key Takeaways:

- Preserve your completed puzzles for years to come by choosing the right storage method. From traditional puzzle storage to innovative solutions like puzzle roll-up mats and storage bags, there’s a method to suit every puzzler’s needs and preferences.

- Whether you want to display your completed puzzle as artwork or keep it organized and protected, there’s a storage solution for you. Consider factors like available space, puzzle size, and portability to select the best method for preserving your hard work.

Read more: How To Store Puzzle

Methods for Storing Completed Puzzles

When it comes to storing completed puzzles, you have a variety of options to choose from. Let’s explore some of the most popular methods:

- Traditional Puzzle Storage Methods: This method involves using a flat surface, such as a table or a piece of cardboard, to carefully transfer the completed puzzle. Once it’s on the flat surface, you can slide it into a puzzle storage box or seal it with plastic wrap. This traditional approach is simple and cost-effective, but it requires ample space and may not provide optimal protection.

- Puzzle Roll-Up Mats: Puzzle roll-up mats are a convenient and space-saving solution. These mats consist of a felt-like material that lays flat on a table or any other flat surface. You simply place your completed puzzle on the mat and then roll it up from one end to the other, securing it with straps or ties. This method allows you to store your puzzle in a compact roll, making it easier to store in a closet or under a bed.

- Puzzle Storage Bags: Puzzle storage bags are designed specifically for storing completed puzzles. These bags often have separate compartments or slots to keep the individual puzzle pieces intact. You can slide your completed puzzle inside the bag, seal it shut, and then store it upright or lay it flat. Puzzle storage bags come in various sizes to accommodate different puzzle dimensions.

- Puzzle Glue and Frame: If you want to display your completed puzzle as a piece of artwork, puzzle glue and framing is the way to go. Puzzle glue is a special adhesive that allows you to fix the puzzle pieces together. Once the glue is dry, you can frame the puzzle and hang it on the wall. This method not only ensures long-term preservation but also adds a decorative touch to your living space.

- Puzzle Sorting Trays: Puzzle sorting trays are handy tools for both assembling and storing puzzles. These trays typically have separate compartments or trays that allow you to sort and store the puzzle pieces based on shape, color, or pattern. Once you complete the puzzle, you can reassemble it on the sorting trays, making it easy to transport and store without worry about losing or damaging pieces.

- Puzzle Storage Organizers: Puzzle storage organizers come in various designs and configurations. You can find storage units specifically designed for puzzle enthusiasts, featuring multiple compartments or drawers to store completed puzzles of different sizes. Some organizers even come with sorting trays or dedicated spaces for puzzle glue and other accessories, providing a comprehensive storage solution.

Whichever method you choose, remember to handle your completed puzzle with care, especially if it’s a large or intricate one. Avoid bending or twisting the puzzle, and always lift it from the edges or use a puzzle mat to support it.

Now that you’re familiar with the different methods for storing completed puzzles, you can select the one that best suits your needs and preferences. Whether you opt for a traditional approach or invest in specialized storage solutions, preserving your completed puzzles will allow you to enjoy and showcase your hard work for years to come.

Traditional Puzzle Storage Methods

Traditional puzzle storage methods are a simple yet effective way to store completed puzzles. This method involves transferring the puzzle from the work surface to a storage container, such as a puzzle storage box or even a large ziplock bag. Here’s a closer look at how to utilize traditional puzzle storage methods:

Transfer the Puzzle: Start by carefully sliding the completed puzzle from the working surface onto a flat and sturdy material, such as a piece of cardboard or a foam board. Ensure that the puzzle remains intact during the transfer process.

Choose a Storage Container: Once the puzzle is on the flat surface, you’ll need to select a suitable storage container. Puzzle storage boxes are readily available and come in various sizes to accommodate different puzzle dimensions. Another option is to use a large ziplock bag or a plastic container with a secure lid.

Protect the Puzzle: If you choose to use a puzzle storage box, carefully slide the puzzle into the box, ensuring it fits snugly without bending or damaging any pieces. You can insert a sheet of wax paper or a large plastic bag between each puzzle layer to prevent sticking. For a ziplock bag or plastic container, slide the puzzle in and seal it tightly to keep out moisture and protect it from dust and debris.

Consider Storage Space: Traditional puzzle storage methods require ample space to accommodate the storage containers. If you have limited space, a puzzle storage box might be the ideal choice as it can be easily stacked. Alternatively, you can store the puzzle flat on a shelf or inside a cabinet, ensuring there’s no unnecessary pressure on the puzzle surface.

Label and Organize: To make it easier to locate specific puzzles in the future, consider labeling your storage containers. You can use sticky labels or write directly on the box or bag. Additionally, you may want to arrange your puzzle storage boxes in a systematic order, such as by puzzle theme, size, or level of difficulty.

Traditional puzzle storage methods offer a straightforward and cost-effective solution for storing completed puzzles. However, keep in mind that the lack of cushioning or protection may pose a risk of damage to the puzzle pieces, especially during transportation or when storing puzzles with delicate or irregularly shaped pieces.

When using traditional puzzle storage methods, make sure to handle the puzzle with care to prevent bending or twisting. Always lift the puzzle from the edges, supporting it from underneath or using a puzzle mat to maintain its structural integrity.

In the next section, we will explore another popular method for storing completed puzzles: puzzle roll-up mats.

Puzzle Roll-Up Mats

If you’re looking for a convenient and space-saving storage solution for your completed puzzles, puzzle roll-up mats are a fantastic option. These mats provide a quick and easy way to store your puzzles while keeping them intact. Here’s how puzzle roll-up mats work:

Lay Out the Puzzle: Start by completing your puzzle on a flat surface. Once you’re satisfied with the finished puzzle, ensure that all the pieces are securely connected and in place.

Prepare the Puzzle Roll-Up Mat: Lay the puzzle roll-up mat on a clean and flat surface, such as a table or the floor. Make sure the mat is fully extended and flat, without any wrinkles or folds. Puzzle roll-up mats are typically made of felt-like material, providing a smooth surface for your puzzle.

Transfer the Puzzle Onto the Mat: Carefully lift the completed puzzle and slide it onto the puzzle roll-up mat, placing it in the center. Take your time while doing this to avoid any accidental damage to the puzzle pieces.

Roll Up the Mat: Once the puzzle is placed on the mat, start rolling it up from one end to the other. Apply gentle pressure to keep the puzzle tight and secure. Some puzzle roll-up mats come with straps or ties to keep the rolled-up puzzle in place.

Store the Rolled-Up Puzzle: Once the puzzle is rolled up, you can store it vertically or horizontally, depending on your preference and available space. Vertical storage allows you to stand the rolled-up puzzle in a closet or against a wall, while horizontal storage allows you to slide it under a bed or other furniture.

Unrolling the Puzzle: When you’re ready to work on your puzzle again, simply unroll the puzzle roll-up mat. The puzzle pieces should remain in place, allowing you to continue where you left off. If any pieces have shifted during storage, gently readjust them to their correct positions.

Puzzle roll-up mats are a convenient storage solution, particularly for those who have limited space or frequently switch between puzzles. They offer excellent protection for your completed puzzle, preventing damage from dust, moisture, or accidental bumps.

It’s important to note that puzzle roll-up mats are available in various sizes, so make sure to choose one that matches the dimensions of your completed puzzle. Some mats also come with sorting trays or storage compartments, allowing you to keep additional puzzle pieces or accessories organized.

Now that you’re familiar with puzzle roll-up mats, let’s move on to the next storage method: puzzle storage bags.

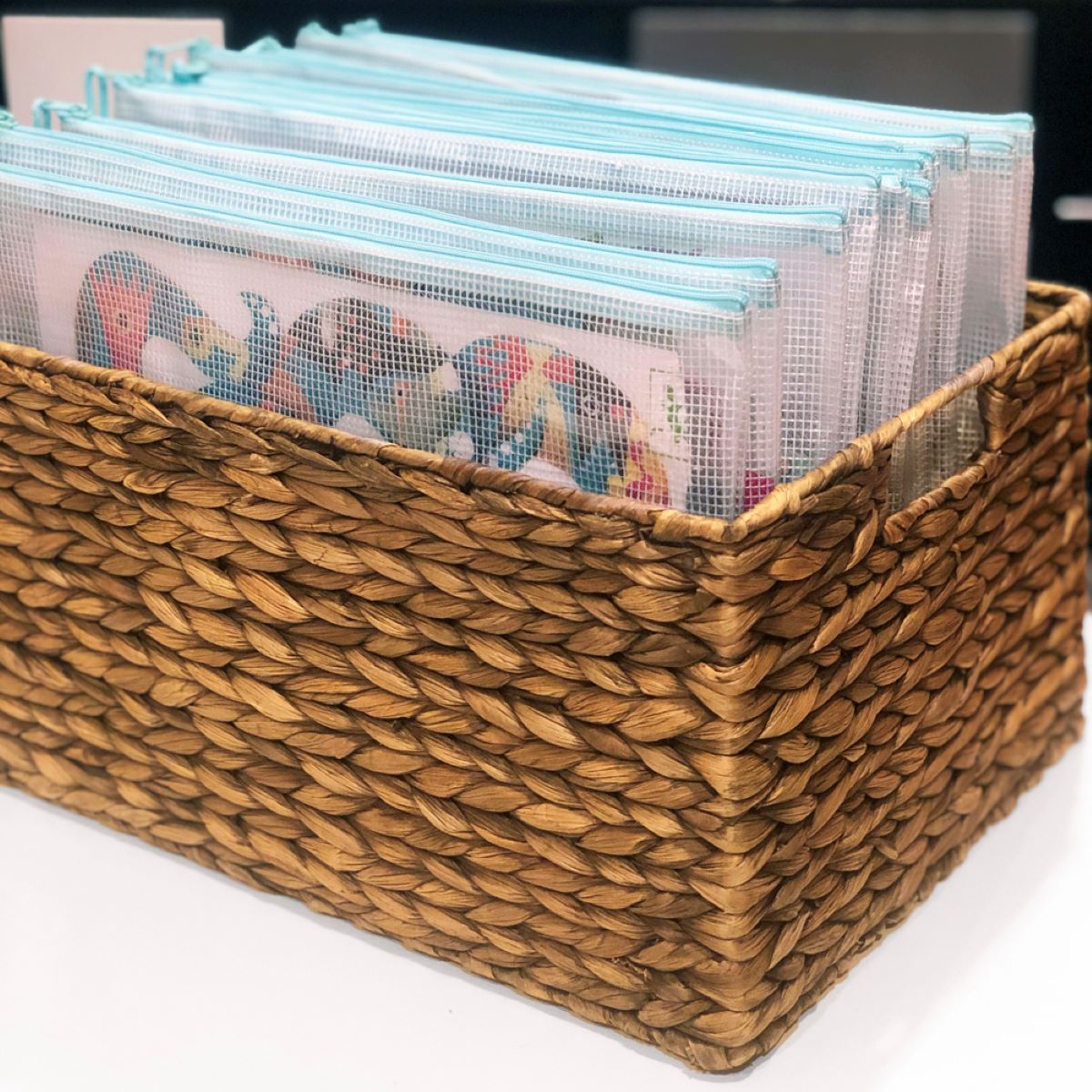

Puzzle Storage Bags

Puzzle storage bags offer a convenient and space-efficient solution for storing your completed puzzles. These specially designed bags provide a safe and secure way to keep your puzzles intact and protected. Here’s how puzzle storage bags work:

Prepare the Puzzle: Once you have completed your puzzle, ensure that all the pieces are securely connected and in place. Check for any loose pieces or gaps in the puzzle that need attention before transferring it to the storage bag.

Select the Puzzle Storage Bag: Puzzle storage bags come in various sizes to accommodate different puzzle dimensions. Choose a bag that is large enough to comfortably fit your completed puzzle without bending or damaging any pieces. Look for bags made of durable materials that provide good protection from dust and moisture.

Transfer the Puzzle into the Bag: Gently lift the completed puzzle and slide it into the puzzle storage bag. Take care to ensure that the puzzle remains intact and doesn’t shift during the transfer. If the puzzle is larger than the bag, you may need to bend or fold the puzzle slightly, but be cautious not to apply too much pressure.

Seal the Bag: Once the puzzle is inside the storage bag, seal it tightly to prevent any dust, moisture, or debris from entering. Most puzzle storage bags come with a ziplock closure or a hook-and-loop fastener for easy opening and closing.

Store the Bag: Depending on your preference and available space, you can store the puzzle storage bag flat or upright. If you have multiple puzzle storage bags, consider organizing them in a designated area or on a shelf to make locating specific puzzles easier in the future.

Puzzle storage bags are not only great for storing completed puzzles, but they also provide a portable storage option. You can easily transport your puzzles using these bags, whether you’re taking them to a friend’s house or storing them in a different location.

It’s important to note that puzzle storage bags are designed to keep the puzzle pieces intact and prevent damage. However, they may not provide the same level of protection as other methods, such as puzzle roll-up mats or puzzle storage organizers. If you have delicate or irregularly shaped puzzle pieces, you may want to consider using additional protective measures like placing a sheet of wax paper or bubble wrap between puzzle layers.

Now that you know how puzzle storage bags work, let’s move on to another popular storage method: puzzle glue and frame.

To store completed puzzles, use a large piece of cardboard or foam board to carefully transfer the completed puzzle. Cover with a sheet of wax paper and stack another puzzle on top if space is limited. This will help protect the puzzle and keep it intact for future enjoyment.

Read more: How To Store A Puzzle

Puzzle Glue and Frame

If you want to display your completed puzzle as a work of art, using puzzle glue and a frame is an excellent option. This method not only preserves your puzzle but also adds a decorative touch to your living space. Here’s how puzzle glue and framing work:

Secure the Puzzle: Before applying puzzle glue, ensure that all the pieces are securely connected and in their correct positions. Double-check for any loose pieces or gaps in the puzzle that need attention.

Choose Puzzle Glue: Puzzle glue is a specialized adhesive that is designed for preserving puzzles. It typically comes in liquid form and can be found at hobby stores or online. You can choose between brush-on puzzle glue or spray-on puzzle glue, depending on your preference.

Apply Puzzle Glue: Start by laying your completed puzzle on a smooth and clean surface. Apply the puzzle glue evenly across the entire surface of the puzzle, using a brush or following the instructions on the puzzle glue packaging. Pay special attention to the edges of the puzzle to ensure that all the pieces are coated.

Allow the Glue to Dry: After applying puzzle glue, allow ample time for it to dry completely. The drying time can vary depending on the type and brand of puzzle glue used. Follow the instructions on the puzzle glue packaging to determine the recommended drying time.

Frame the Puzzle: Once the puzzle glue is completely dry, you can frame your puzzle. Choose a frame that matches the dimensions of your completed puzzle. You may need to consider custom framing if your puzzle has non-standard dimensions. Carefully slide the puzzle into the frame and secure it following the frame’s instructions.

Puzzle glue and framing not only protect your completed puzzle from damage but also allow you to showcase your hard work and creativity. Once framed, the puzzle becomes a piece of artwork that can be hung on the wall or displayed on a shelf.

It’s important to note that puzzle glue permanently fixes the puzzle pieces together, making it difficult or impossible to disassemble the puzzle in the future. Therefore, before using puzzle glue and framing, ensure that you are committed to preserving the puzzle as a permanent display.

Now that you’re familiar with using puzzle glue and a frame, let’s move on to the next puzzle storage method: puzzle sorting trays.

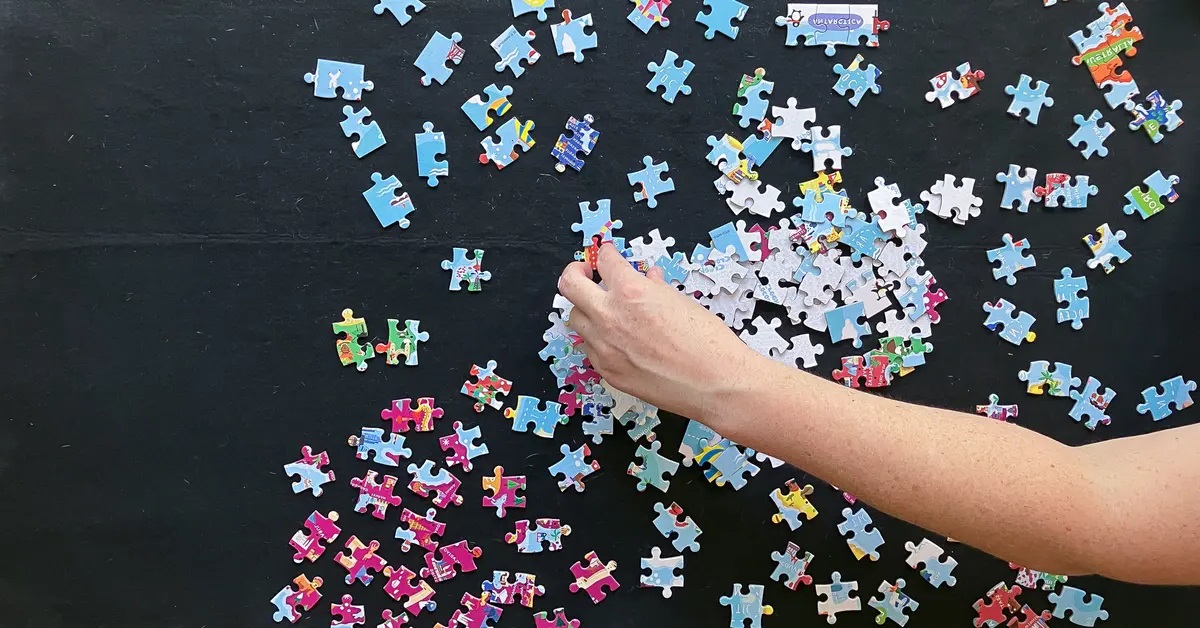

Puzzle Sorting Trays

Puzzle sorting trays offer a practical and efficient way to not only assemble puzzles but also store them. These trays provide separate compartments or trays to sort and organize the puzzle pieces, making it easier to work on the puzzle and maintain its integrity. Here’s how puzzle sorting trays can be utilized:

Sort the Puzzle Pieces: Before assembling your puzzle, it’s helpful to sort the pieces based on their shape, color, or pattern. This can be done by placing the puzzle pieces into separate compartments of the sorting tray.

Assemble the Puzzle: Once the puzzle pieces are sorted, you can start assembling the puzzle directly on the sorting trays. The separate compartments allow easy access to the pieces and help prevent them from getting mixed up or lost.

Store the Puzzle: When you’re not actively working on the puzzle, you can leave the assembled pieces on the sorting trays, keeping them organized and intact. Some puzzle sorting trays come with a lid, allowing you to cover and protect the puzzle while it’s being stored.

Transport the Puzzle: Puzzle sorting trays are particularly useful if you need to transport your puzzle to a different location. The trays help secure the puzzle pieces and keep them organized during transportation, reducing the risk of losing or damaging pieces.

Puzzle sorting trays come in various sizes and configurations to accommodate different puzzle dimensions and piece counts. Some trays have adjustable compartments, allowing you to customize the size and arrangement of the sections. This flexibility makes them suitable for puzzles of different complexities and sizes.

Using puzzle sorting trays not only enhances the efficiency of assembling puzzles but also simplifies the puzzle storage process. By keeping the puzzle pieces organized and contained, you can preserve the puzzle’s integrity and minimize the risk of losing or damaging pieces.

Now that you understand the benefits of puzzle sorting trays, let’s move on to the final puzzle storage method: puzzle storage organizers.

Puzzle Storage Organizers

Puzzle storage organizers offer a comprehensive and versatile solution for storing completed puzzles. These organizers combine various features, such as storage compartments, sorting trays, and additional accessories, to provide a convenient and efficient storage method. Here’s a closer look at puzzle storage organizers:

Storage Compartments: Puzzle storage organizers typically have multiple compartments or drawers to store completed puzzles. These compartments are designed to accommodate puzzles of different sizes, allowing you to store multiple puzzles in one organizer.

Sorting Trays: Many puzzle storage organizers come equipped with sorting trays. These trays provide separate sections for sorting and organizing the puzzle pieces, making it easier to access and assemble the puzzle. Sorting trays help prevent mixing up pieces and ensure a more efficient puzzle-solving experience.

Dedicated Spaces for Accessories: Puzzle storage organizers often include dedicated spaces or compartments for accessories like puzzle glue, puzzle mats, and additional tools. This allows you to keep all your puzzle-related items in one place, making it convenient to access and use them when needed.

Customizable Configurations: Some puzzle storage organizers offer customizable configurations, allowing you to adjust the size and arrangement of the compartments or trays based on your specific needs. This flexibility ensures that the organizer can accommodate puzzles of different dimensions and piece counts.

Portability: Puzzle storage organizers are designed to be portable, allowing you to easily transport your completed puzzles. Many organizers have handles or built-in straps, making it convenient to carry them to your desired location. This makes them a great option if you want to take your puzzles on the go or store them in a different area.

Puzzle storage organizers provide a comprehensive solution for puzzle enthusiasts who want to keep their completed puzzles organized, protected, and readily accessible. With the various compartments, sorting trays, and additional features, these organizers offer both functionality and convenience.

When selecting a puzzle storage organizer, consider the size and number of puzzles you plan to store. Choose an organizer that can accommodate your collection and provides enough compartments to keep the puzzles separated and intact.

Now that you’re familiar with puzzle storage organizers, you have a wide range of options to choose from. Find the organizer that suits your needs and preferences, and enjoy the convenience and organization it brings to your puzzle storage solution.

Conclusion

Storing completed puzzles is essential to preserve your hard work and keep them intact for years to come. From traditional puzzle storage methods to innovative solutions, there are various options available to suit your needs and preferences.

Traditional puzzle storage methods offer a simple and cost-effective approach. By transferring your completed puzzle onto a flat surface and storing it in a puzzle storage box or ziplock bag, you can protect it from dust and debris. However, these methods may not provide optimal protection or organization.

Puzzle roll-up mats are a convenient and space-saving solution. With these mats, you can easily roll up your completed puzzle and store it vertically or horizontally. This method is ideal for those with limited space or who frequently switch between puzzles.

Puzzle storage bags provide a compact and portable option for puzzle storage. These bags come in different sizes and keep the puzzle pieces intact while protecting them from dust and moisture. They are a great choice for those who want to transport their puzzles or store them in smaller spaces.

If you want to display your completed puzzle as a work of art, puzzle glue and a frame are the ideal choice. By applying puzzle glue to seal the pieces together and framing the puzzle, you can create a beautiful and permanent display.

Puzzle sorting trays offer a practical way to assemble and store puzzles. With separate compartments or trays, they make it easier to sort and organize puzzle pieces. These trays keep the pieces secure and prevent loss or damage during storage or transportation.

Puzzle storage organizers provide a comprehensive solution, combining storage compartments, sorting trays, and dedicated spaces for accessories. They offer versatility and convenience, ensuring that your completed puzzles are organized, protected, and easily accessible.

When selecting a storage method, consider factors such as available space, the size of your puzzles, and your preferences for organization and portability.

By utilizing these various storage methods, you can protect your completed puzzles, keep them organized, and showcase them as a delightful reminder of your hard work and accomplishment. Choose the storage solution that suits your needs and preferences, and enjoy the satisfaction of preserving your completed puzzles for years to come.

Frequently Asked Questions about How To Store Completed Puzzles

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Completed Puzzles”